Manufacture's Feature

|

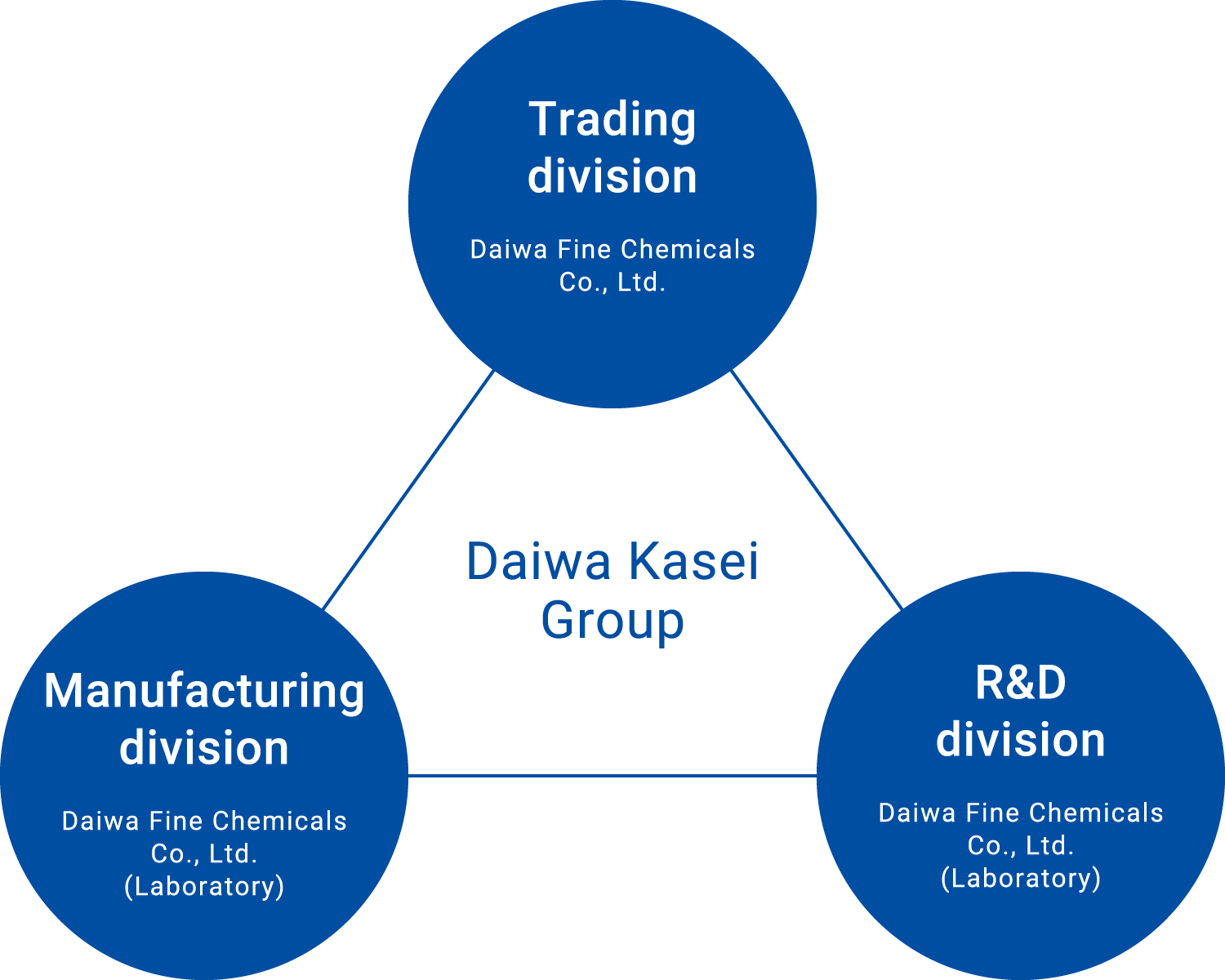

Synergy is at our core, and we will continue to spread our wings.。 There are three business divisions within the two companies that comprise the Daiwa Kasei Group. The Trading Division exists within Daiwa Fine Chemicals Co., Ltd., and the Research & Development and Manufacturing Divisions exist within Daiwa Fine Chemicals Co., Ltd. (Laboratory). Speed is a critical requirement for research and development work but the organic relationships among our three divisions allows us to both to faster develop the products and technologies our customers are looking for and to quickly respond to the problems they face. |

Synergy, for the Daiwa Kasei Group, produces three key strengths。

|

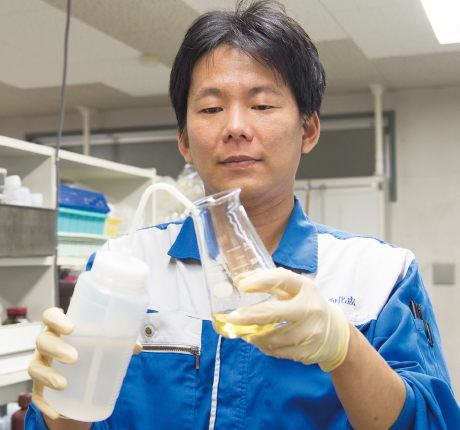

The R&D Division at Daiwa Fine Chemicals Co., Ltd. (Laboratory), has

opened up new and unique paths for the company, challenging us to do things

that no one else has done before. We’ve focused on specific fields, identifying

niche markets that few other companies are involved in, to dive deeper

into our technologies and to develop unique products. We have also worked

hard to create an environment that allows for the talents of each of our

research personnel to shine.

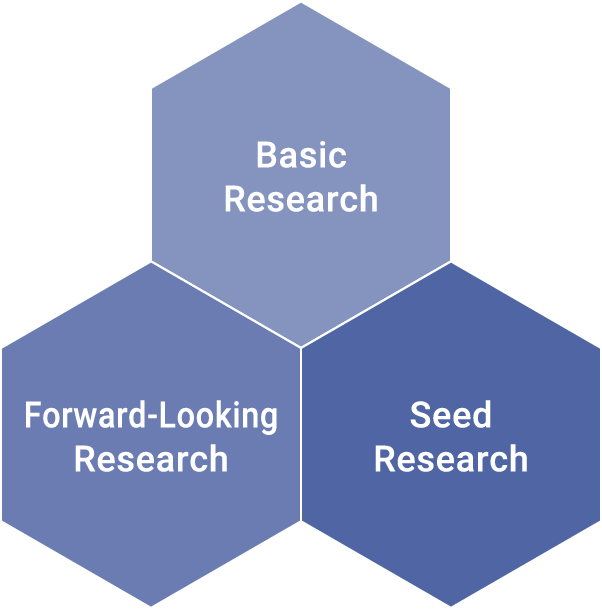

The R&D Division at Daiwa Fine Chemicals Co., Ltd. (Laboratory), has

opened up new and unique paths for the company, challenging us to do things

that no one else has done before. We’ve focused on specific fields, identifying

niche markets that few other companies are involved in, to dive deeper

into our technologies and to develop unique products. We have also worked

hard to create an environment that allows for the talents of each of our

research personnel to shine. We have established

a consistent quality assurance system based on the international standard

ISO9001. We work together with the R&D department to check the manufacturing

process with the aim of consistently providing quality that our customers

are familiar and satisfied with. We pay particular attention to the analysis

of hazardous substances, and are working to strengthen our quality control

system and improve measurement accuracy.

We have established

a consistent quality assurance system based on the international standard

ISO9001. We work together with the R&D department to check the manufacturing

process with the aim of consistently providing quality that our customers

are familiar and satisfied with. We pay particular attention to the analysis

of hazardous substances, and are working to strengthen our quality control

system and improve measurement accuracy.