Manufacture's Feature

|

|

| We aim to unlock greater growth together with our stakeholders as a fine chemical company that speeds up the evolution of industries. | |

Osamu Noma,President

|

2510 million yen

179 (as of March 31 2022)

Small scale production / Oxidation, Heavy metal compound / No-pressure distillation / High temperature reaction (over 200 C degree) / Radical polymerization / Drying, (No-pressure/Vacuum) / Bromination / Ullman reaction / Metallic sodium, Metallic potassium / Hydrogen cyanide, Sodium cyanide, Potassium cyanide / Reduction, Nitro compound / Mizoroki-Heck reaction / Oxidation, Peroxide / Vacuum distillation / Reduction, Metalic hydride / Chlorination / Nitration / Acylation / Organic lithium / Negishi cross coupling / Rectification / Reduction, Catalytic / Column purification / Fluorination / Diazotization / Grignard reaction / Optical resolution / Spray drying / Hydrogeneration / Oxidization, Air / Iodination / Acid chlorides / Reaction, NaNH2 / Thin film distillation / Diazo-coupling reaction / Diazocoupling / Sonogashira-Hagihara Cross Coupling / Polycondensation / Oxidization, Halogenide / Steam distillation / Fluorine compound / Reaction, NaH / Suzuki-Miyaura cross coupling / Sandmeyer reaction / Dehydrogenation / Reduction, High/Middle-pressure / Molecular distillation / Flaker / Sulfonation / Organic sodium / Phosphoric compound / Extraction / Amination / Chlorosulfonation / Solution polymerization / Crystallization / Sulfonamidation / Oxidation, Nitric acid / Reduction, Birch / Optical resolution / Alkylation / Nitrosation / Reaction, Toxic substances / Coupling reaction / Wolff-Kishner-reduction / Aldol reaction / Reduction, Na/Li / Recrystallization / Wittig reaction / Filtration / Etherfication / Metal contents reduction / Esterification / Epoxidation / Carbonylation / Kolbe-Schmitt reaction / Diels-Alder / Cyanation / Hydroxylation / Vilsmeier reaction / Fries rearrangement / Friedel-Crafts reaction / Hofmann's Reaction / Formylation / Michael addition / Mannich reaction / Cyclization / Ring-Opening reaction / Dealkylation / Dehalogenation / Dehydration / Rearrangement / Acid amide / Dehydrogenation / Decarbonation / Quaternarization of Amine, Benzyl oxide /

|

|

| We aim to unlock greater growth together with our stakeholders as a fine chemical company that speeds up the evolution of industries. | |

Osamu Noma,President

|

| Products for various Industries | |

| Beginning with intermediates for dyes and pigments, we have moved into a number of other fields including pharmaceutical and agrochemicals while expanding our extensive product lineup to include fine chemicals. We also retain much proprietary production technology as well as engage in development and production of products ranging from niche to the ordinary. | |

| Pharmaceutical Intermediates |

Our all-round technology of contract manufacturing based on rich experience with organic synthesis, advanced manufacturing technology, and thorough quality control allows us to supply pharmaceutical intermediates to pharmaceutical companies around the world. We contribute to improvement of Quality of Life through the supply of our intermediates in the future too. |

| Active Ingredients and Intermediates for Agrochemicals |

We manufacture active ingredients and intermediates for fungicides, insecticides, and herbicides which are essential to increase agricultural productivity. Our active ingredients and intermediates have a high reputation in Western countries whose environmental criteria is very severe. We contribute to improvement of global food problem through the supply of our products in the future too. |

| Functional Chemicals |

Beginning with monomers for optical and electronic materials with the highest refractive index in the world, our unique products are used for a wide range of fields and industries. In the future, we will challenge development of unique, high value-added products in cutting edge fields. |

| Surfactants |

Industrial surfactants used in various applications such as cleaning, emulsification, liquefaction, disinfection, and electrostatic prevention, are our most important products. Our surfactants are widely used for dispersant of paints, agrochemicals, and ink, and they support our life. |

| Intermediates for Dyes and Pigments |

Intermediates for Dyes and Pigments are the origin of Sugai. Our products with high purity, manufactured by unique organic synthetic technology accumulated for a long period, have a high reputation from customers. Final products manufactured from our dye intermediates are used for a wide range of dyes and colorants for cotton fibers, synthetic fibers, chemical fibers, paper & pulp, leather, hair dye, and cosmetics. Our pigment intermediates are provided as raw materials for printer ink, various paints, and cosmetics. |

| Proposal of the most Appropriate Process for Customers based on our Diverse Reactive Technologies | |||||||||||||||||||||||||||||||||||||||

| Through much results and experience as a custom manufacturer so far, we have been accumulating a great store of divers reactive technologies including oxidation, reduction, Grignard reaction, halogenations, and cyanation reaction which are at the top level among custom manufacturers in Japan. Recently we have been also actively trying to establish new technologies, such as optical resolution, asymmetric synthesis, and flow synthesis. Combination of these wide range of organic synthesis technologies makes it possible to achieve efficient development of target products responding with our customers’ diverse, sophisticated requirement. |  |

||||||||||||||||||||||||||||||||||||||

| 主要な反応技術 | |||||||||||||||||||||||||||||||||||||||

| Acylation | Alkylation | Allylation | Amination | ||||||||||||||||||||||||||||||||||||

| Bromination | Carboxylation | Chlorination | Condensation | ||||||||||||||||||||||||||||||||||||

| Coupling | Cyanation | Esterification | Fluorination | ||||||||||||||||||||||||||||||||||||

| Formylation | Hydroxylation | (Meta)acrylation | Nitration | ||||||||||||||||||||||||||||||||||||

| Oxidation | Optical Resolution | Reduction | Ring formation | ||||||||||||||||||||||||||||||||||||

| Sulfonation and Chlorosulfonation | |||||||||||||||||||||||||||||||||||||||

Examples of Reactions Using the Above Technologies |

|||||||||||||||||||||||||||||||||||||||

| Synthesis of complex compounds with combination of multiple unit process. | |||||||||||||||||||||||||||||||||||||||

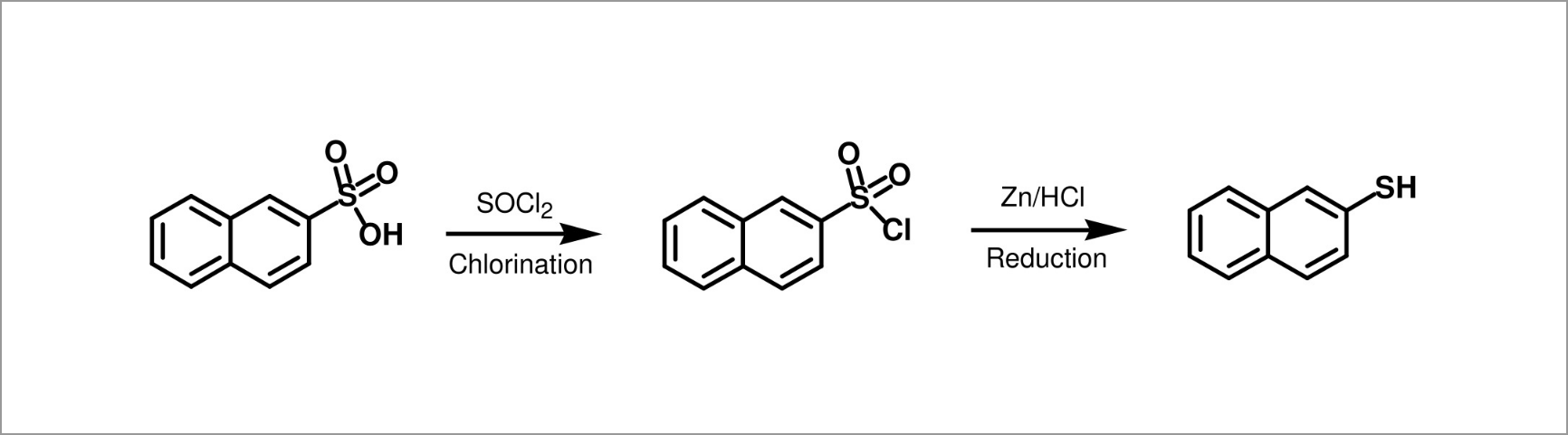

Reaction Example (1): |

|||||||||||||||||||||||||||||||||||||||

| Naphthalenesulfonic acid → (Chlorination) → naphthalenesulfonyl chloride → (Reduction) → naphthothiol | |||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

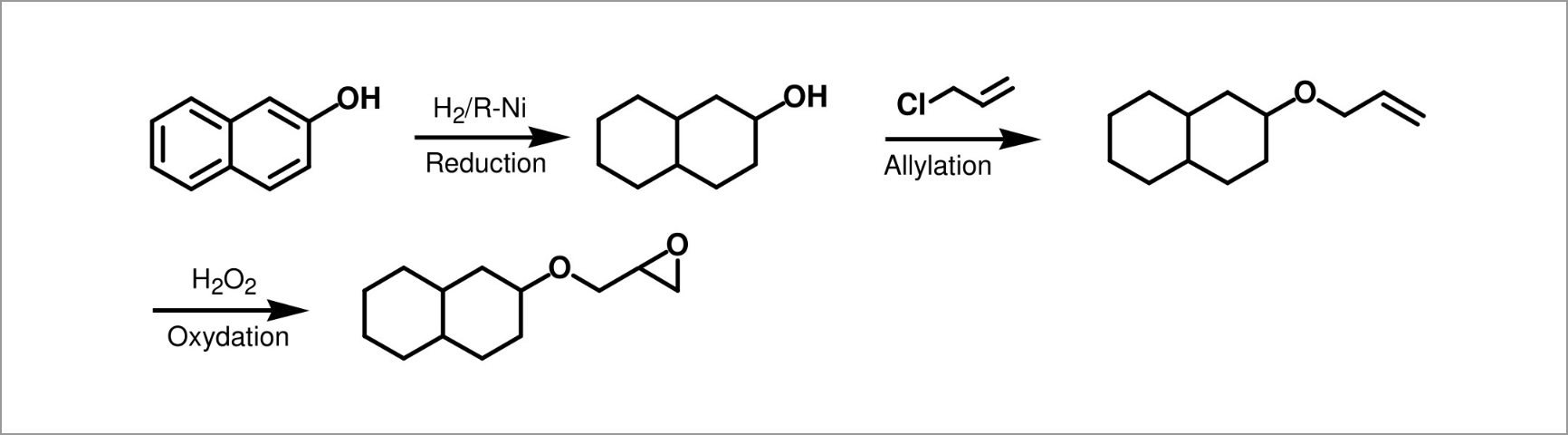

Reaction Example (2): |

|||||||||||||||||||||||||||||||||||||||

| Naphthol → (Reduction) → Hydroxy-decahydronaphthalene → (Allylation) →

Allyloxy-decahydronaphthalene → (Oxidation) → Glycidyloxy-decahydronaphthalene |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

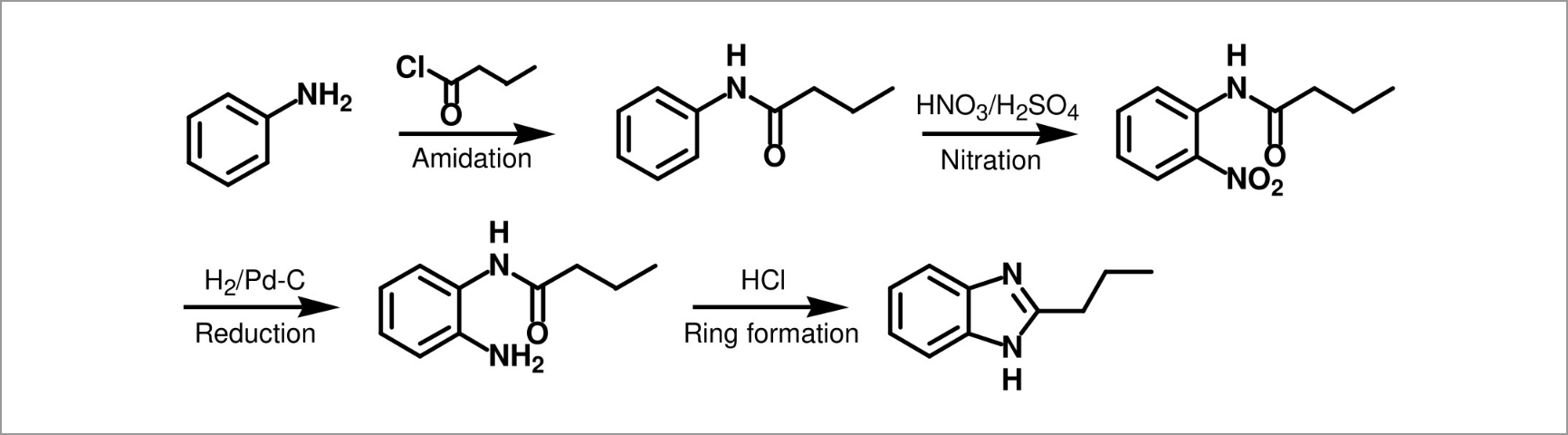

Reaction Example (3): |

|||||||||||||||||||||||||||||||||||||||

| Aniline → (Amidation) → 1-Butyl aminobenzene → (Nitration) → 1-Butylamino-2-nitrobenzene → (Reduction) → 1-Butylamino-2-aniline → (Ring formation) → 2-Propylbenzene imidazole | |||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| Overall support from research and development stage through commercial production |

||

| Provision of our overall support from research and development stage through commercial production that helps customers’ development with high reliability. In the research and development stage, we closely examine customers’ needs through market research, and then it promotes the development and production of original products. | ||

| Research and Development Stage |

1. Literature research We conduct literature research to propose the best possible synthetic method and process, even when only the target compound is indicated without the synthetic information. 2. Laboratory research We optimize synthetic process through laboratory research to address customers’ requirement accurately. We propose appropriate solution to problems identified during lab experiments based on our extensive know-how of organic synthesis. Additionally, we proactively share information with regard to the status of laboratory research, and provide support of customer’s development collaboratively. |

|

| Scale-up Stage | 3. Kilo lab We are fully capable of scale-up production requiring kilogram scale of material by appropriate equipment such as up to 50 L reactor vessels, 300 mm diameter Nutsche funnel, and 10 L SUS press filter. 4. Pilot plant We conduct pilot production on which several kilograms to several dozen kilograms of target material is produced in accordance with the synthetic process established in the laboratory research, and then we optimize the industrial manufacturing process based on results and data of the pilot production. In addition, we also respond to pilot production to provide sample required for customer’s development. |

|

| Production Stage |

5. Trial production We conduct trial production in commercial plant to check whether there are any problems or scale-up effect. In case we find any problems, we return to the laboratory research to investigate solutions, and then we establish the optimal productive conditions on retrial production.。 6. Commercial production We conduct commercial production (campaign production) according to the productive condition established on trial production. In case of necessity even on commercial production stage, we return to the laboratory research to ensure safe and stable operations. We also work to improve productivity and continued cost reduction. |

|

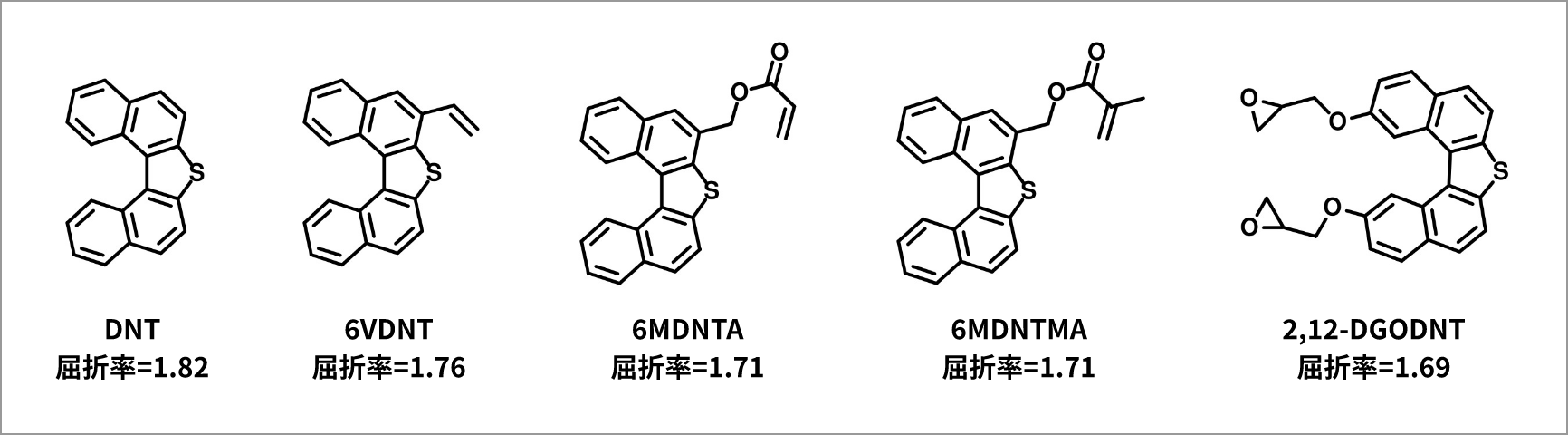

| Dinaphthothiophene Derivatives | View More | |

| Dinaphthothiphene (DNT) is a compound with a very extremely high refractive index (1.82 at 589nm) as a single organic chemical substance. We meet customers’ requirement by providing various derivatives of DNT with functional groups by our best organic synthesis technologies. Representative derivatives are shown as below. | ||

|

||

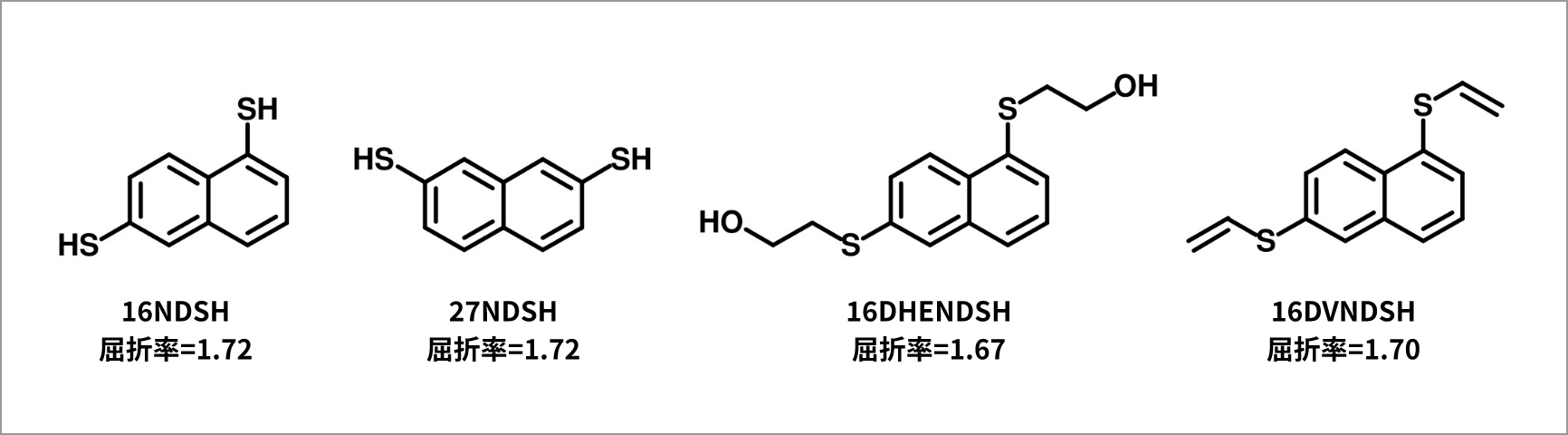

| Naphthothiol Derivatives | View More | |

| Naphthothiol and its derivatives have very refractive index among other organic compounds. In particular, the 1,6-derivative has both high refractive index and good solubility (compatibility), and we can also supply various derivatives with polymerizable groups. | ||

|

||

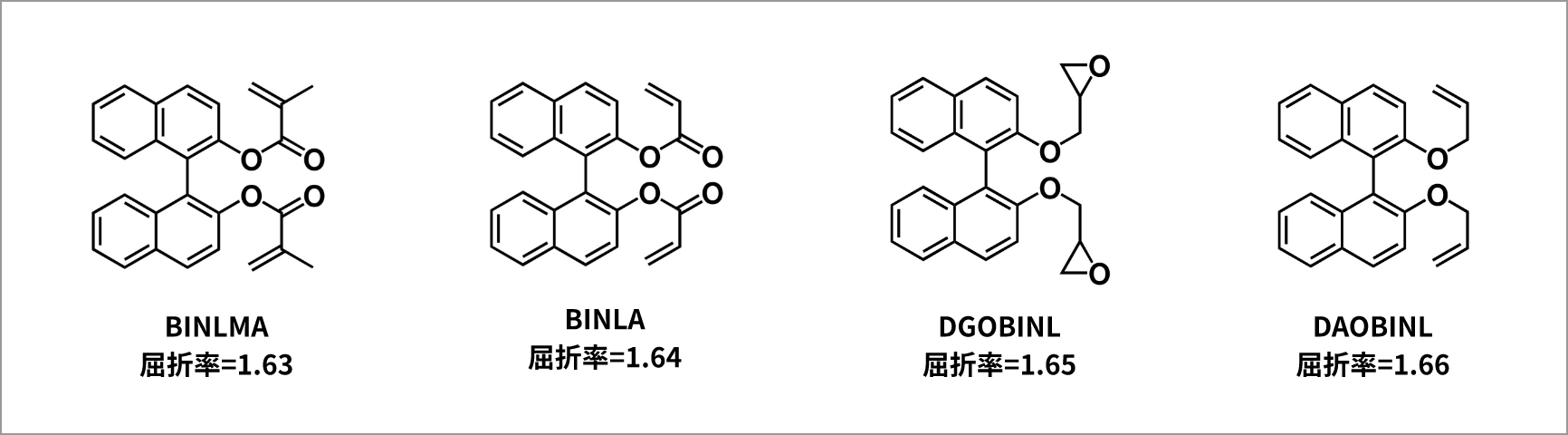

| Binaphthol Derivatives | View More | |

| Binaphthol derivatives have high value in use as organic compounds with a high refractive index, and we can supply various derivatives. | ||

|

||

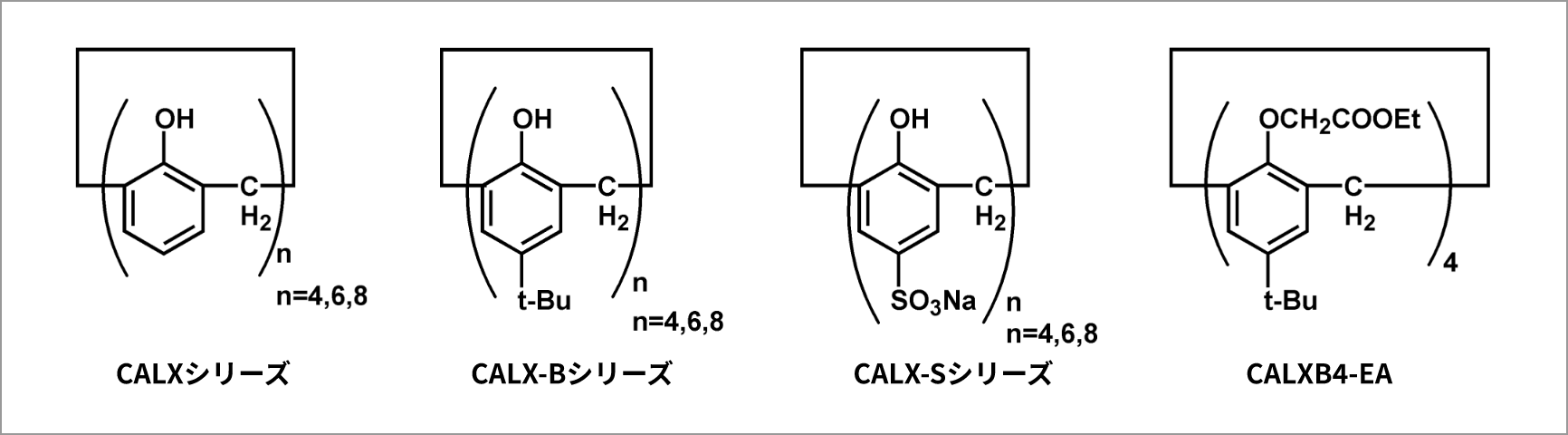

| Calixarenes | View More | |

| We have two main types of Calixarenes such as S series (n=4,6,8) with sulfonic group and B series (n=4,6,8) with tert-butyl group. Also, we can supply CALXB4-EA that is used for additive of cyanoacrylate adhesive. Development of monomers with polymerizable groups is also expected. Representative derivatives are shown as below. |

||

|

||

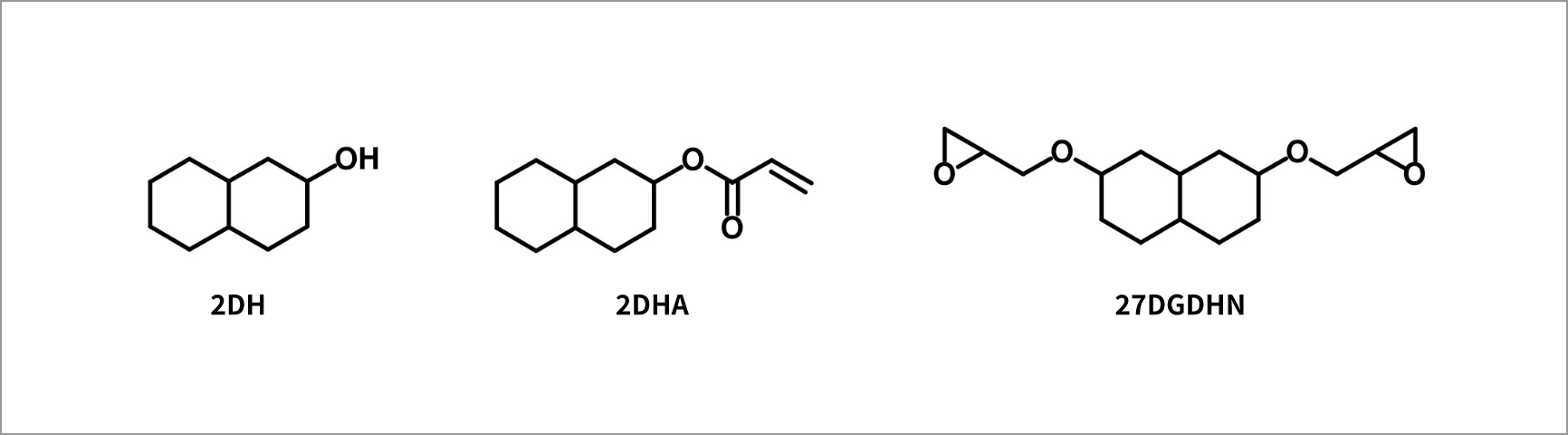

| Decaline Derivatives | ||

| We develop 2DH, 2DHA (acrylate), and 27DGDHN (glycidyl ether) have high heat-resistant and transparent property. These Decaline derivatives are expected to be used for optical area. | ||

|

||

| Diverse facilities |

|

| Our manufacturing facilities are multipurpose. We address a broad range

of customers’ needs with accuracy, flexibility, and swiftness, including

provision of several grams of sample through commercial production of several

dozen tons of product. |

|

| Laboratory research (30 to 5,000 mL) |

Reactor vessels and separatory flasks (30 to 5,000 mL), SUS autoclave (100 to 3,000 mL), Glass-lining autoclave (300 to 1,000 mL), SUS Press filter (200 mL), Glass-lining press filter(1 L), Rectifying column, Thin-film evaporator, Pure water system, Ultrapure water system, Constant temperature and humidity oven, Refrigerant device (minimum -15 ℃), Vacuum dryer, Homogenizer, Light flow synthesizer, Syringe pump, etc. |

Laboratory |

|

| Kilo lab (10 to 50 L) |

Reactor vessels (10 to 50 L), Mantle heater, Separatory flasks (10 L), SUS Press filters(1.5 to 10 L), Nutsche funnel (300 mm diamete), Glass filter (185 mm diameter), Vessels (up to 100 L), etc. |

| Pilot plant (50 to 2,000 L) |

Fukui Research Institute (pilot plant) |

Inside of Fukui Research Institute (three stories) Inside of Fukui Research Institute (three stories) |

|

| Trial production (3,000 to 12,000 L)) |

|

| Commercial production (3,000 to 12,000 L) |

Reactors |

Thin-film evaporator Thin-film evaporator |

|

| Analytical instruments | HPLC, GC, GPC, GC-MS, LC-MS, DSC, TG/DTA, IC, Reaction calorimeter, Atomic absorption spectrophotometer, Combustion ion chromatography, IR moisture meter, Karl Fischer moisture meter, pH meter, B-type viscometer, UV spectrophotometer, IR spectrophotometer, Digital microscope, Automatic titrator, Colorimeter, Turbidity meter, Total organic carbon (TOC) meter, Conductivity meter, Vacuum dryer, Electric furnace, Pure water system, Ultrapure water system, etc. |

HPLC HPLC |

|

| Quality Engagement | ||

| We have obtained ISO 9001 certification which is international quality management system for the entire company including research departments, and we have ensured that we are constantly improving quality. Additionally, we conduct thorough quality control on all stage from research and development through commercial production. We not only maintain this high level of quality, but also work toward continuous improvement of quality to take our production technologies to the next level. | ||

| Quality Policy |

We respond to expectations and needs from customers, and we continue to improve so that we can always provide quality to customers’ gain trust and satisfaction. | |

| ISO 9001 Certification for Quality Management System We have obtained ISO 9001 certification so that we can constantly provide high quality products and service to gain customers’ trust and satisfaction. We will continue efforts to maintain and improve quality through development and manufacture of fine chemicals with high quality in the future too. |

||

|

||

| Applicable Standard | JIS Q 9001 : 2015(ISO 9001 : 2015) | |

| Registration Date | March 16, 1998 | |

| Certification No. | JCQA-0304 | |

| Registered Section | Company-wide | |

| Wakayama Site Wakayama Nishi Factory | |

|

|

|

| Fukui Site / Fukui research Institute | |

|

|

|